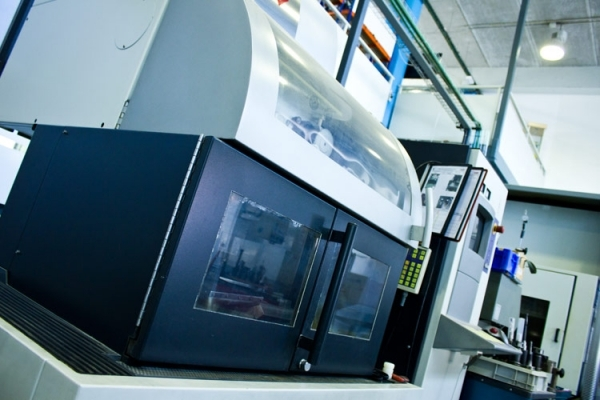

Wire EDM

Wire EDM machining is used for high-precision cutting of conductive materials.

It is possible thanks to the jump of electrical discharges that takes place between the electrode and the part to be machined. It is a thermoelectric process, in which the sparks produced represent a thermal point source that will melt the material of the part, thus producing erosion. In addition, deionized water is used, which will help the jump and therefore the quality of the sparks, to cool the material already eroded and to eliminate the material removed.

Advantages

- Working with conductive materials that have relevant thickness.

- No pre-machining of the electrode necessary.

- It is a high precision process with controlled variable angularity.

- Consistent results: Allows the same part to be reproduced over and over again.

- Complex shapes can be achieved.

- Allows machining of previously hardened materials.

Applications

- Cutting of extremely hard materials and workpieces without mechanical effort.

- Erosion of conductive materials.

- Very thick metal parts (which would not be cut by laser or water) where precision is desired and productivity is not important (slow process).

- Very small parts such as injector pins or needles for medical use.

- Parts with very thin walls.

- utting of stacked materials: no need for clamping devices or supports.

- Cutting of tiny radius.

Equipment available

Equipment that from wire EDM allows the manufacture of metal tools and prototypes, with a high level of precision and quality surface finishes. It is used for the machining of parts made of conductive materials that have a high thickness or density and allows to reduce the machining time of these parts.

One of its main characteristics is that it can be used for texturing metal surfaces, as well as machining, which makes it ideal for the manufacture of tools for plastic injection molding and other processes for the manufacture of plastic parts, as this is the area of greatest application of this process.

Features

- Number of axles: 4

- Potential difference: 100-250 Volts

- Maximum cutting speed: 240 mm/min

- Maximum piece weight: 500 kg

- Yarn diameter: 0.1 – 0.3 mm